Sodium Carboxy methyl cellulose

Price 375.0 INR/ Kilograms

Sodium Carboxy methyl cellulose Specification

- Physical Form

- Powder

- Product Type

- Sodium Carboxy methyl cellulose

- Shelf Life

- Minimum 2 years under optimal storage conditions

- Appearance

- White to off-white powder

- Ingredients

- Sodium Carboxymethyl Cellulose (CMC)

- Density

- 0.7 Gram per cubic centimeter(g/cm3)

- Poisonous

- Non-poisonous

- Molecular Weight

- Approx. 262.19 g/mol (may vary with degree of substitution)

- Storage

- Store in tightly sealed container in a dry, cool, and ventilated place, away from direct sunlight and moisture

- Molecular Formula

- C6H7O2(OH)2OCH2COONa

- Melting Point

- Decomposes before melting

- Solubility

- Soluble in water, insoluble in most organic solvents

- Shape

- Fine powder

- Usage

- As directed per specific industrial requirements

- Purity

- High purity (typically 99%)

- Properties

- High viscosity, excellent water solubility, forms stable colloids, thickening, binding, emulsifying, stabilizing agent

- Grade

- Industrial Grade, Food Grade, Pharmaceutical Grade

- Structural Formula

- -O-[C6H7O2(OH)2OCH2COONa]-

- Smell

- Odorless

- CAS No

- 9004-32-4

- Application

- HS Code

- 39123100

- EINECS No

- 618-378-6

- Ph Level

- 6.58.5 (1% solution)

- Taste

- Odorless and tasteless

- Loss on Drying

- 10%

- Compatibility

- Compatible with most hydrophilic substances

- Bulk Density

- 0.40.7 g/ml

- Degree of Substitution (DS)

- 0.61.2

- pH (1% solution, 25C)

- 6.58.5

- Particle Size

- 80120 mesh

- Heavy Metals

- 0.002%

- Viscosity (2% Solution)

- 4004000 mPas (depending on grade)

- Packaging

- 25 kg / 50 kg net bags or as required

About Sodium Carboxy methyl cellulose

Used in a variety of applications. From food products to medical teatment. Usually used as a viscosity modifier. Non toxic and generally hypoallergenic. Non food products include Laxatives, Tooth paste, Water based Paints and Detergents. Used in ice creams under E466 or E469 to increase viscosity. Enhances grease removal in food vessels and laundry. Also used in ice packs to increase cooling capacity than ice.

Exceptional Versatility in Industrial Applications

Sodium Carboxymethyl Cellulose is widely used for its thickening, stabilizing, emulsifying, and binding abilities. It imparts desirable texture and stability to products in food processing, pharmaceuticals, textiles, detergents, and paper manufacturing. Its adaptability to various viscosities and grades enhances its utility across diverse sectors.

Reliable Quality and Safety Standards

Produced with high purity ( 99%) and stringent controls, CMC meets international standards (HS Code: 39123100, EINECS No: 618-378-6). With low heavy metal content (0.002%), it is recognized as non-poisonous, odorless, and safe for diverse applications. Its long shelf life and optimal storage stability further ensure product reliability.

Easy Handling and Storage

This fine powder is easy to handle and dissolves rapidly in water, forming stable colloidal solutions. It should be stored in a sealed container in a dry, cool, well-ventilated area, away from direct sunlight and moisture to preserve its performance and extend shelf life beyond two years.

FAQ's of Sodium Carboxy methyl cellulose:

Q: How is Sodium Carboxymethyl Cellulose (CMC) typically used in various industries?

A: CMC is employed as a thickener, stabilizer, binder, and emulsifier in food products, pharmaceuticals, textiles, detergents, and paper. Its functional versatility enables manufacturers to improve product texture, stability, and processing characteristics according to specific industrial requirements.Q: What are the benefits of using CMC with a degree of substitution of 0.6-1.2?

A: A degree of substitution (DS) between 0.6 and 1.2 strikes a balance between solubility and functionality. It ensures efficient dissolution in water, optimum viscosity control, stable colloid formation, and compatibility with most hydrophilic substances, enhancing product performance across applications.Q: When and how should CMC be added during the production process?

A: CMC is best incorporated early in the production process, dissolved gradually into water or aqueous systems under continuous stirring. This ensures uniform dispersion and prevents clumping, allowing it to develop the required viscosity and functional properties in the final product.Q: Where should Sodium Carboxymethyl Cellulose be stored to maintain its quality?

A: It should be stored in tightly sealed containers, kept in a dry, cool, and ventilated place, away from direct sunlight and moisture. Proper storage preserves its quality, prevents caking, and ensures a minimum shelf life of two years.Q: What makes CMC a safe and non-toxic option for industrial and food applications?

A: CMC is a high-purity, non-poisonous compound with very low heavy metal content (0.002%). It has no odor or taste, is stable in neutral pH, and complies with recognized international safety standards, making it suitable for sensitive applications like food and pharmaceuticals.Q: How does the viscosity of CMC affect its use in different applications?

A: CMC is available in various viscosity grades (400-4000 mPas for a 2% solution). Higher viscosities offer stronger thickening and stabilizing effects, making them ideal for applications needing enhanced texture or suspension, while lower viscosities are preferred where easy flow or solubility is vital.Q: What are the recommended packaging options for Sodium Carboxymethyl Cellulose?

A: CMC is commonly supplied in 25 kg or 50 kg net bags, but packaging can be customized based on customer requirements to ensure safe storage, handling, and transportation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Chemical Category

Soda Ash - Light/Dense/Food Grade

Price 30.0 INR / Kilograms

Minimum Order Quantity : 1000 Kilograms

Physical Form : Granule, Other

Shelf Life : 1 Years

Shape : other

Purity : 99.5%

Citric Acid Anhydrous

Price 65 INR / Kilograms

Minimum Order Quantity : 1000 Kilograms

Physical Form : Powder

Shape : Crystal

Purity : 99.5%

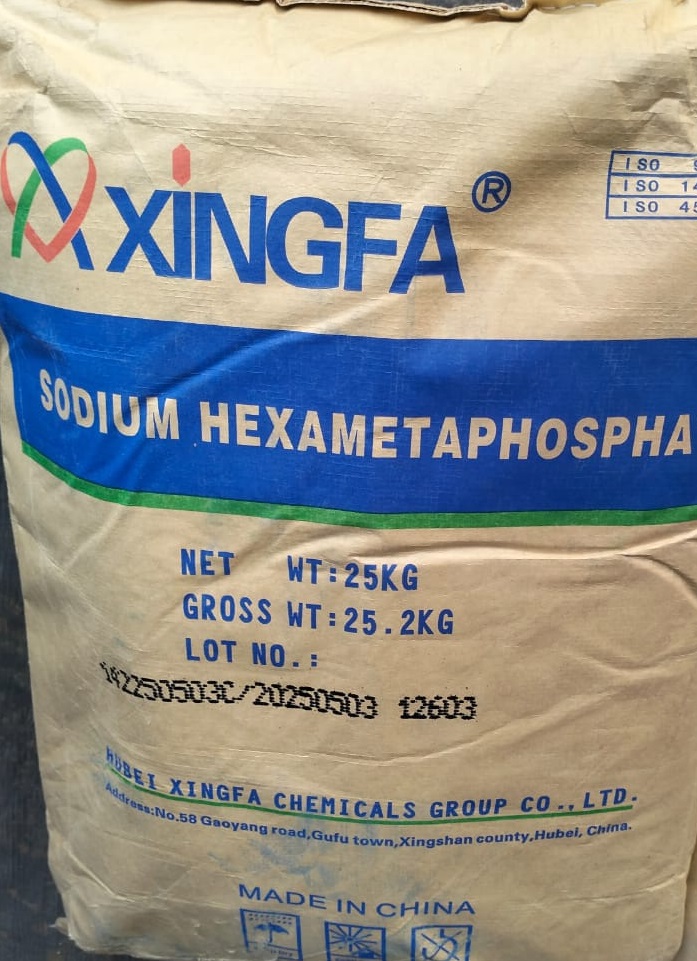

SODIUM HEMAMETA PHOSPHATE

Price 121.0 INR / KGS.

Minimum Order Quantity : 5000 Kilograms

Physical Form : Powder

Shelf Life : 18 Months

Shape : other

Purity : 68%

Caustic Soda Flakes (Sodium Hydroxide)

Price 44 INR / Kilograms

Minimum Order Quantity : 1000 Kilograms

Physical Form : Powder

Shelf Life : 1 Years

Get a Quote

Get a Quote

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese